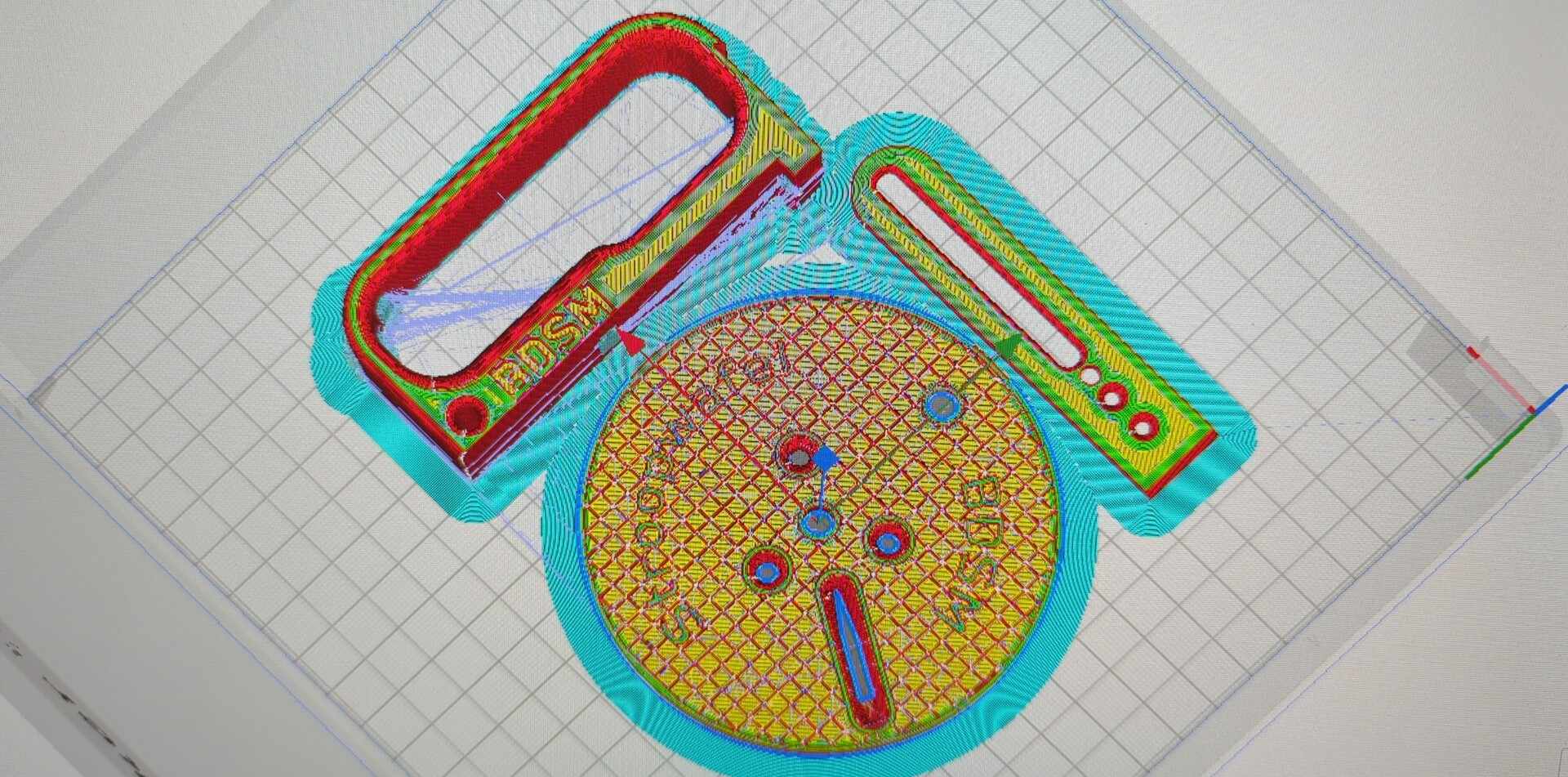

Printing a reel

I have a thing that happens in my brain, maybe it’s because of a brief time as a person who made things, that I think I can make things. It means that I’m pretty resourceful, but it’s also got me into some serious pickles over the years. I’ve thought about it a lot, and I’m able to catch myself before I get into serious trouble—mostly—but I’ve found an upside to it.

By making things myself, I appreciate how hard it is to do a good job of it. I also understand much better why things are the way they are. I Appreciate croissants a lot more after trying a couple of times to make them!

So with that preamble, I’ve been thinking about getting into cave diving, and a cave reel costs upwards of $300, which is quite a lot for something that looks a lot like something that you can get from Bunnings for under $10. So, this is a process of understanding where all that extra value gets generated.

|

|

|

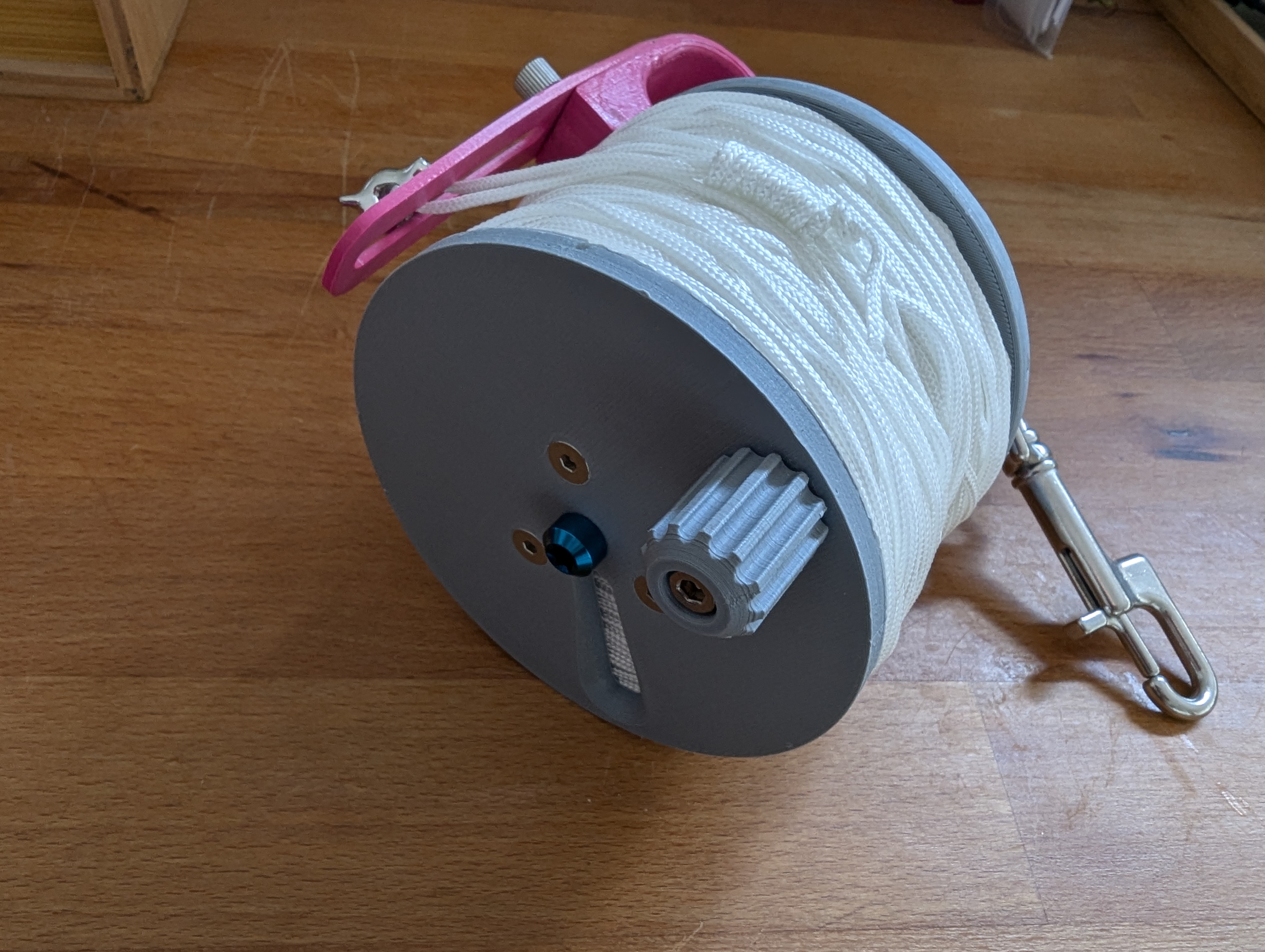

The “finished” reel

This is where I ended up. There are a few tweaks to make, but I’m happy enough with this one to get stuck into some land drills with it. This is the process of getting here:

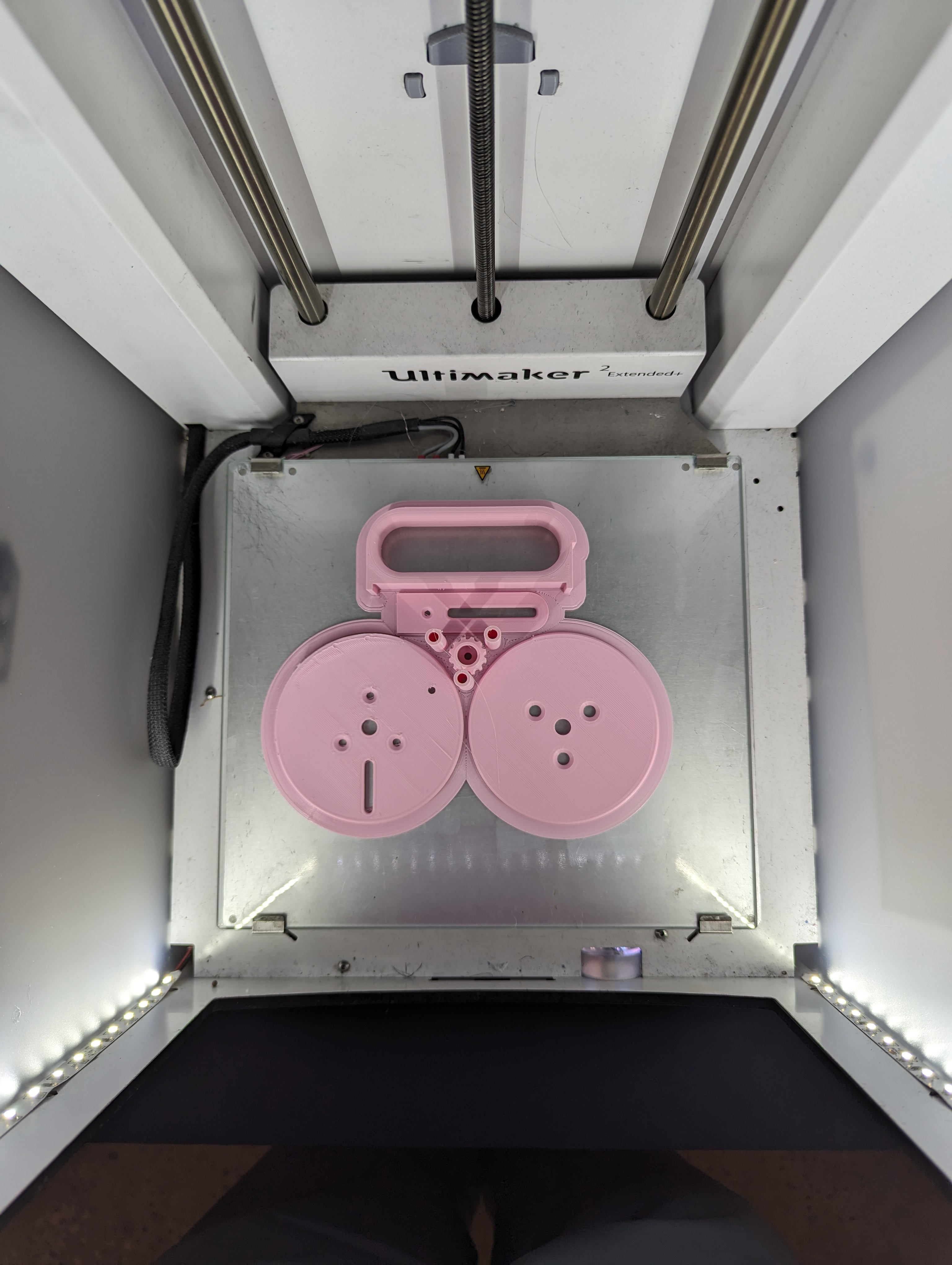

The evolution of the handle

I got three pieces of Delrin from Ali Express, all 100×100mm, one 20mm, and two 5mm. The plan was that the handle came from the 20mm piece, and the cheeks of the reel would come from the 5mm pieces. That set the thickness of the handle, an the max diameter of the cheeks.

The first handle, checking for hand size, was a polystyrene shape cut out on a hot wire cutter.

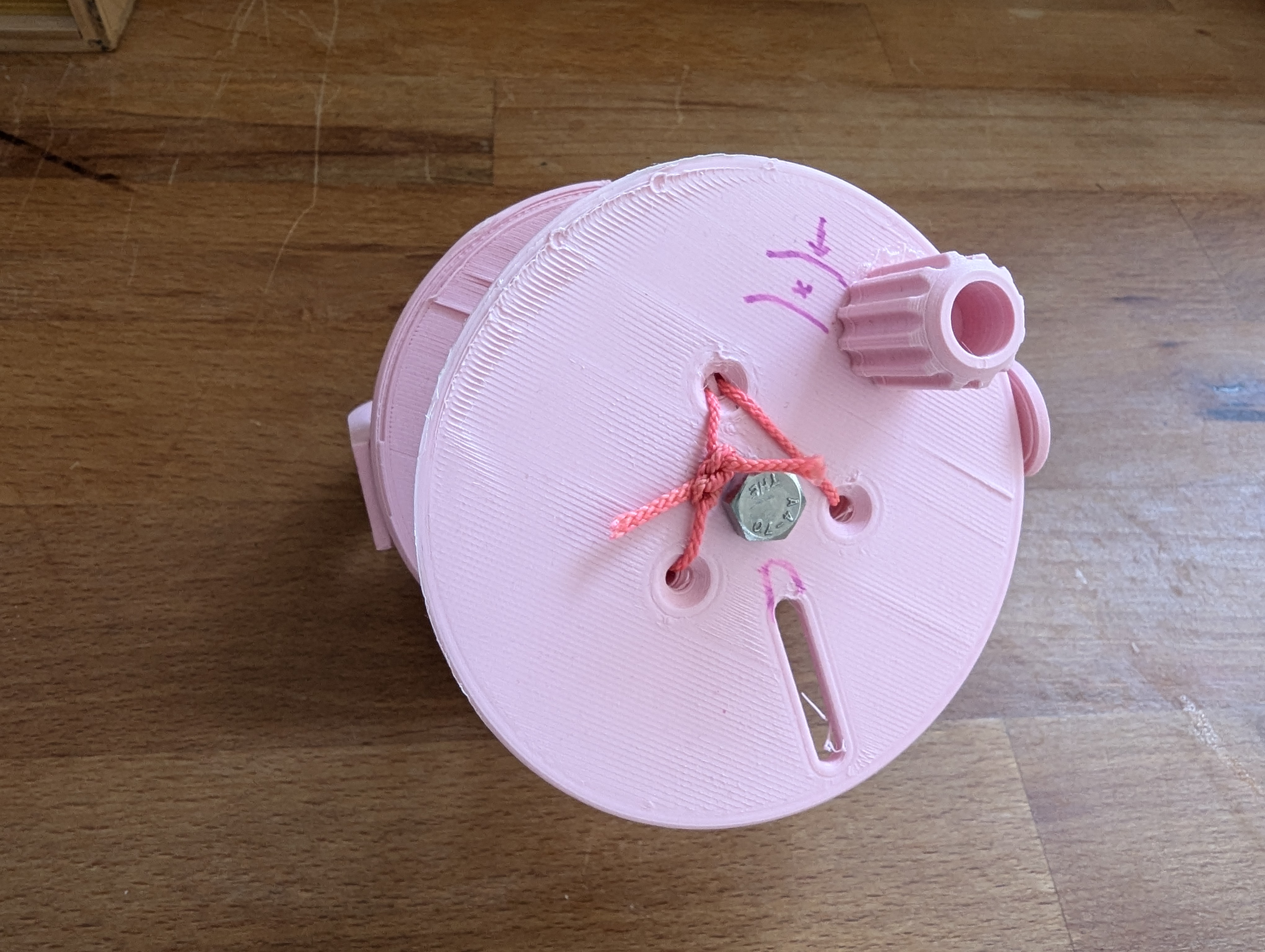

Fully assembled first prototype

The first one I made assumed that I needed to capture the cheek of the spool at both ends. That meant that I needed to make the spool really small to accommodate all the stuff at the top end, and still sit under the chin at the bottom.

I learnt a lot of things from this one though; the whole point of making prototypes!

Mainly that the spool could hang off the side of the handle. That meant that the spool could be the full 100mm of the Delrin sheet. The reason I’m so obsessed about making the most of the Delrin is that it’s really expensive. So that’s probably one of the reasons that the commercially available reels are so expensive.

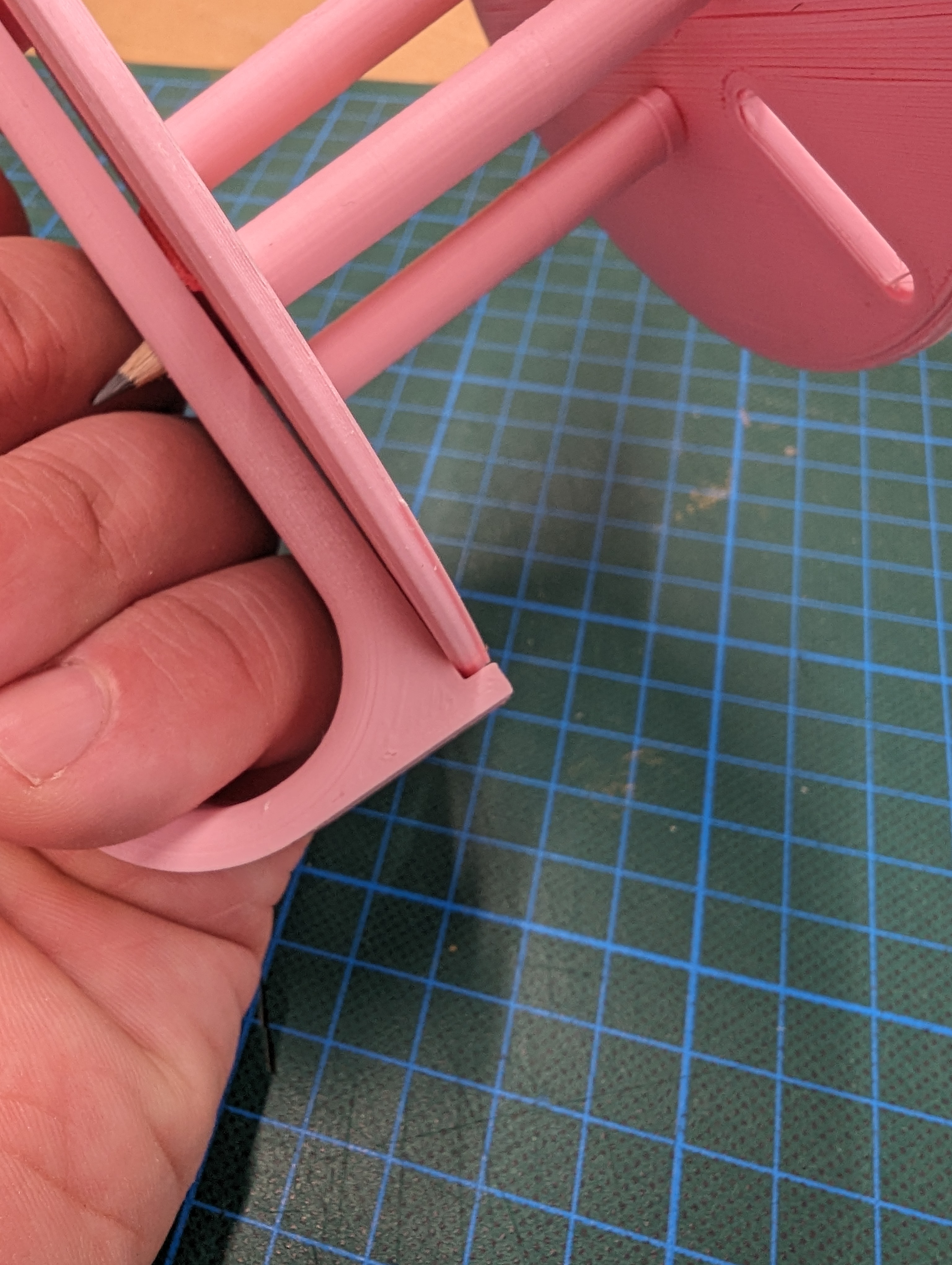

The other things were details that are a lot easier to notice when the thing is in your hands, rather than rotating on a screen. I like being able to write on a print; treating it as a thing that can be gouged and written on makes it much more useful.

The other big thing is that you can’t really thread a bolt into a PLA print, so the final version has a lot of heat-set brass inserts in it.

I’m going to do some land drills with the reel, and see if anything else needs to be changed. If I like it, I’ll machine it out of Delrin, and then probably buy a commercially available one.

P.S.

Cave diving is obsessed with cookies, and one of my favourite cookies is the stroopwafel

P.P.S.

Ben Doherty Side Mount (BDSM)

16/02/2025 Some land based testing

Some line laid in Henson Park

I finally got a chance to test it out doing what it’s supposed to do. As a 3d printed jankey thing it’s not too bad at all! However, the ergonomics needs a bit of a tweak. My thumb got really tired while holding it, so I think it needs a wider area to rest my thumb. The Halcyon reels don’t have a hole at all, and I can see what they’re thinking (even if I don’t like it).